WHY IS SERVO TECHNOLOGY BETTER FOR MOTION SYSTEMS ?

At MFS, we strive for excellence and only use top-of-the-line materials in our motion platforms. Our extensive experience and understanding of advanced technologies allow us to ensure the highest standards at a competitive price.

Instead of relying on traditional stepper or AC-DC motors, we have made the deliberate choice to solely use servo motors. This technology provides numerous benefits, including unparalleled precision, lightning-fast response times, substantial torque outputs, energy efficiency, versatility, reliability, and seamless integration with other components

By choosing servo motors, we are able to deliver motion platforms that meet the highest standards and exceed expectations.

ADVANTAGES OF WORKING WITH SERVO TECHNOLOGY INCLUDE :

High precision control: Servo motors can be controlled with high precision, allowing for accurate positioning and repeatability. In other words, our servo motors are capable of accurate position control, allowing for repeatable and precise movements in even the most demanding application.

Fast response time: Servo motors have fast response times, making them suitable for high-speed applications.

High torque: Servo motors can generate high torque outputs, which makes them suitable for heavy loads and high-force applications.

Energy efficiency: Servo motors are more energy efficient than other types of motors, making them ideal for applications where power consumption is a concern.

Flexibility: Servo motors can be used in a variety of applications, including position control, speed control, and torque control, making them a versatile choice for motion control.

Robustness: Servo motor technology is robust and reliable, making it suitable for use in harsh environments and demanding applications.

Integration: Servo motors can be easily integrated with other components, such as sensors, controllers, and drives, to create a complete motion control system.

COMPARISON WITH OTHER TECHNOLOGY

Servomotors are generally used as a high performance alternative to the stepper motors.

Stepper motors have some inherent ability to control position, as they have built-in output steps. This often allows them to be used as an open-loop position control, without any feedback encoder, as their drive signal specifies the number of steps of movement to rotate. This lack of feedback though limits their performance, as a stepper motor can only drive a load that is well within its capacity, otherwise missed steps under load may lead to positioning errors.

The encoder and controller of a servomotor are an additional cost, but they optimize the performance of the overall system (for all of speed, power and accuracy) relative to the capacity of the basic motor.

With larger systems, where a powerful motor represents an increasing proportion of the system cost, servomotors have the advantage.

This leads to the fact that motion systems may be offered in two ranges, the low-priced range using stepper motors and the high-performance range using servomotors.

MFS definitely offers high performance and high fidelity at a great price !

IMPROVED PERFORMANCE AND DESIGN

MFS servo technology offers a speed bandwidth of 1,600 Hz, providing exceptional response times.

With a power density of 548 W/I, our systems pack maximum power into a compact design, reducing the overall footprint and decreasing costs.

EASED ENGINEERING, INSTALLATION AND COMMISSIONING

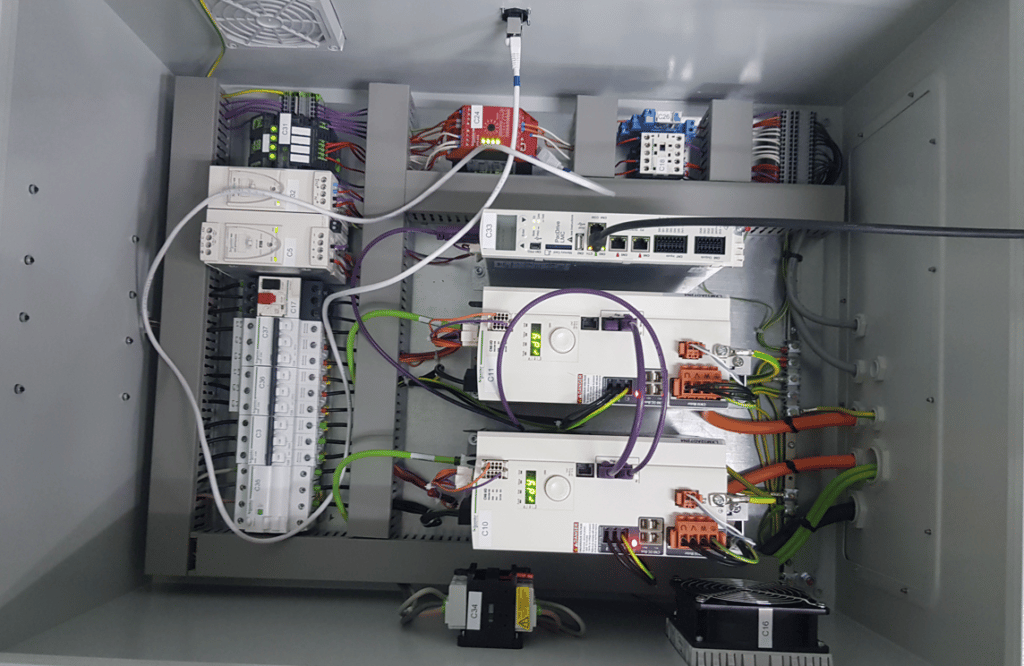

Our Autotuning function simplifies tuning for precise control. The Lexium 32 offers features for quick installation and maintenance, such as removable, color-coded connectors and integrated interface software, making it one of the most powerful systems available.

INTEGRATED SAFETY

Our servo technology features “Safe Torque Off” on board (IEC/EN 61800-5-2) for shorter downtimes and less wiring. The optional enhanced safety module (eSM) provides access to 551, 552, SOS, and SLS safety functions for added peace of mind.

MEETING INDUSTRY STANDARDS

Our servo motors meet all standards and offer unparalleled power density, covering a continuous stall range from 1.2 to 260 Nm for speeds up to 8000 RPM.

They are certified as “Recognized” by the Underwriters Laboratories and conform to UL 1004 standards as well as to European directives (e marking).

Our servo systems have 2 degrees of protection for the shaft end: IP 50 or IP 65 (IP 67 with the conformity kit, which is available as an option) in accordance with standard IEC/EN 60529. The degree of protection of the casing is IP 65 (IP 67 with the conformity kit, which is available as an option)

SPECIAL FEATURES

Our servo motors are designed to comply with the following main specifications:

The ambient operating temperature is- 20 … + 40° ( without derating, in accordance with standard IEC 60721-3-3 category 3K3, and up to 55° ( with derating of 1 % of the nominal output power per additional 0c abo i1e 40°C.

The maximum operating altitude is 1000 m without derating, 2000 m with k = 0.86 and 3001 > m with k = 0.8 (1 ).

The relative humidity that the servo motor can withstand is in line with standard IEC 60721-3-3, categories 3K3, 3Z12 and 3Z2.

The windings are insulation class F (maximum temperature for windings 155°() in accordance with standard IEC 60034-1.

The thermal protection is provided and controlled by the Lexium 32 servo drive via the motor temperature control algorithm.

INSPIRED BY SIMPLICITY

Our servo driven systems provide you the drive and motor combination that has exactly the right power, performance and functionality and that comes at the right price.