CUSTOM UPPER PLATFORMS

TAILORED TO YOUR UNIQUE REQUIREMENTS

Each project is unique, and so should each upper platform be. While motion platform manufacturers may only provide a basic triangular or rectangular platform, we understand the importance of customizing it to your specific needs.

Designing an upper platform requires specialized knowledge and expertise to ensure that it performs optimally, without any issues such as resonance, brake parts, safety hazards, noise, or collisions with the floor or platform itself.

That’s why we believe it’s our responsibility to design and build your custom upper platform, taking into consideration its design and selecting the appropriate motion equipment.

We understand the importance of flexibility and ease of transportation, which is why we typically build your upper platform in modular segments, allowing for seamless transport.

WHY IS CUSTOMIZATION NECESSARY ?

Material selection: Steel is commonly used for heavy loads, while aluminum is more suitable for lighter loads. Other materials such as carbon fiber or composite materials can also be used, depending on the specific requirements of the project.

Size and shape: Customizing the size and shape of the platform to match the specifications of the project is a crucial aspect of the design process. The platform should fit the equipment and payload it will support, as well as the available space in the motion simulator.

Load capacity: Customizing the load capacity of the platform is important to ensure that it can support the weight of the payload and any other equipment it will be used with.

Accessibility: Customizing the platform to allow for easy access to the payload and any other equipment is important for maintenance and repair purposes. Allow for easy integration of custom stairways and ramps.

Surface finish: Customizing the surface finish of the platform can improve its appearance and reduce the likelihood of slipping or other safety hazards.

Integration with other equipment: Customizing the platform to integrate with other equipment, such as motion systems, control systems, or sensors, can improve the overall performance of the simulator.

Safety features: Customizing the platform to include safety features, such as guardrails, emergency stop buttons, or redundant backup systems, can enhance the safety of the simulator

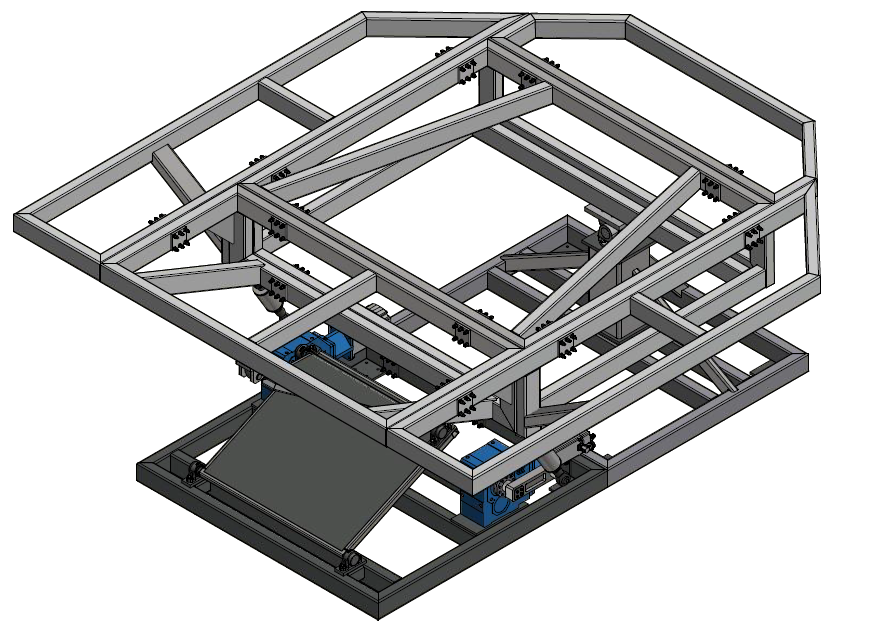

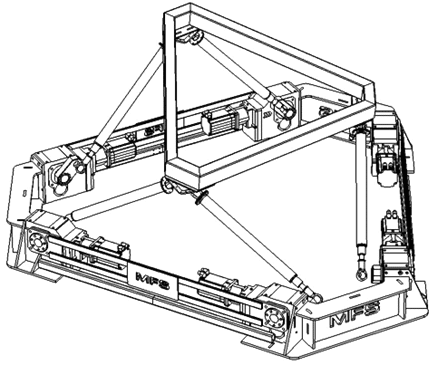

EXAMPLES OF OUR WORK

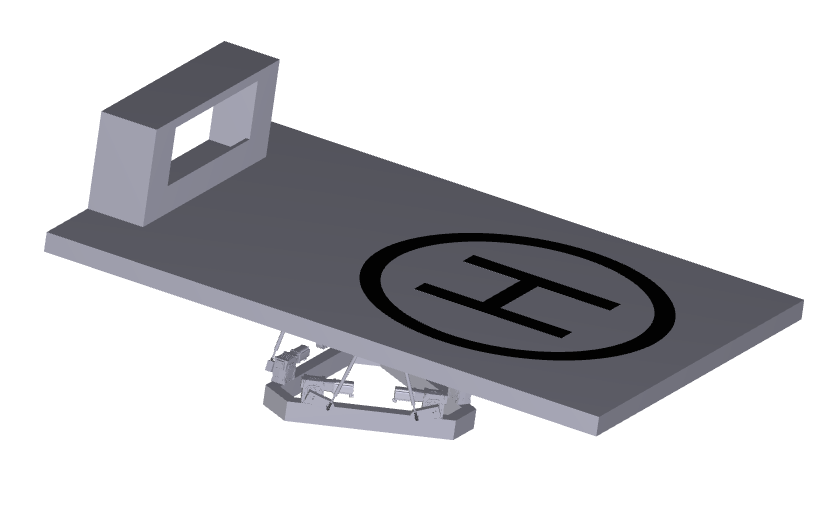

This illustration showcases a custom-designed and built upper platform by our company, This platform was created for a research and development project, where the customer required a 6DOF landing deck to test drone autolanding and takeoff capabilities in various sea states. The platform is used to mimic sea motion, enabling land-based testing that eliminates the need for costly and time-consuming sea trials, with the goal of improving drone technology.

Additionally, the whole system can be anchored on a moving truck, simulating the movement of a boat and providing even more realistic testing conditions. Furthermore, the motion platform can be designed in a foldable way to allow for easy transportation, making it a versatile solution for companies looking to test and improve their drone technology in various locations. The cabin seen on the extension was added for the safety of the operator and is reinforced to withstand an impact from the drone, ensuring that the operator is protected during testing procedures